If you’re running a manufacturing business, then you probably know how important including new technologies is. If your business requires you to ingrain barcodes and similar identification marks onto your products, then getting a fiber laser marking machine might be the best option for you. These machines are low-maintenance, easy to operate, extremely precise, and offer many functionalities.

Of course, the first question that might pop up is how to use this useful technology? Well, it definitely won’t require hours of training!

In this article, we will answer all of your questions about these machines and more. So without further ado, let’s get started!

Table of Contents

Read the manual

Source: pinterest.com

This machine is a pricey investment to make, so you have to make sure that you know how to use it properly. It’s relatively easy to learn, but it might take some time if you don’t have much prior experience. Make sure to train your staff if you’re not the one who will be using it the most, and ensure that every single person that comes in contact with the equipment knows how to operate it properly.

All quality fiber laser machines will come with a detailed manual. Read it carefully, and make sure to have it nearby if you forgot any necessary steps. There are also many YouTube tutorials for this, so if you’re a visual learner, don’t hesitate to look online too. Just make sure it’s the same model since not all-fiber laser machines operate in the same way.

All in all, the operating manual is your best friend, so don’t ignore it and don’t try to learn through trial and error. This would only make it harder for you, and it could lead to unnecessary damage and delays in your work.

Learn about maintenance and care

Source: facebook.com

Not properly maintaining the machine is the worst thing you can do. If your machine is left without necessary care, the risk of malfunction and damage is much higher. So yes, you have to learn proper maintenance if you want it to last long. Even if it doesn’t completely break down, why suffer through unnecessary repair expenses if you’re perfectly capable of avoiding this scenario?

Don’t worry, the machine is actually not that hard to maintain. For the most part, your focus should be on the optical assembly. You have to ensure that the lenses are well protected since they’re the only thing stopping your costly laser from being damaged.

Another important thing is to clean the lenses properly. While doing so, proceed with care and be as gentle as possible. Try to avoid handling them with your bare hands, and make sure they don’t come in contact with any hard surfaces. These pieces of equipment are incredibly delicate, and you don’t want them to be damaged since they can be pretty costly to replace.

Lastly, make sure that your staff is well-trained when it comes to maintenance because you don’t want any unnecessary damage to your equipment.

Find a good supplier

Source: geekyviews.com

When you’re purchasing your first fiber laser machine, make sure you get a high-quality one. You don’t want to be forced to replace it or constantly repair it, since this could end up being much pricier than investing in a more high-quality one at the very beginning.

When choosing the seller of these machines, make sure they offer some after-sales service like they do at hispeedlaser.com. It’s also important to check for any available warranties since these are extremely expensive and you don’t want to have to buy a completely new one if the recently purchased machine malfunctions. Make sure the company has good customer service and that they can provide you with all the important information you may require.

Other than that, do your research and look for customer feedback and online reviews of the supplier before you buy the machine. Buying only from reliable manufacturers is key to any purchase and this especially goes for large investments like the fiber laser machine.

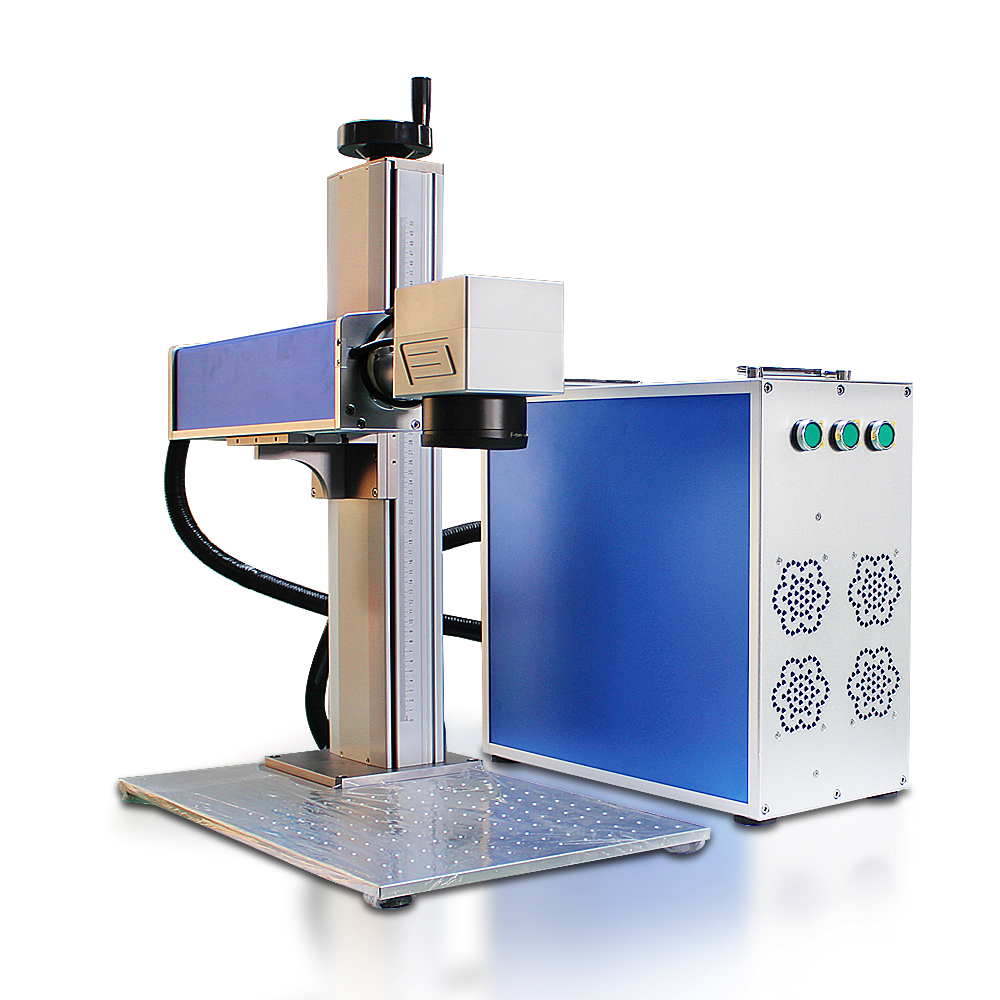

The general process of operating a fiber laser machine

Source: toolots.com

Generally, the process of operating this practical piece of equipment is very simple. First of all, most of these support USB input for the design. You should check what formats are supported by your machine, but usually, jpg pictures should be fine. Your manual will provide you with enough detail to know which setting is the best for the material you’re using. If you’re not sure, you should ask your supplier for advice. After that, you should do a test marking to ensure the settings are appropriate. Once you’re pleased with the results, then it’s time to finish the marking on your product. After you’re done with using it, ensure that the machine is unplugged and protected appropriately.

The process is not complicated at all, but you should still look into the manual for the specific details. Every machine is different, and it’s always better to check the manual before operating the machine. As previously mentioned, your operator has to be well-trained and knowledgable to ensure the best results possible.

Other important tips for successfully operating a fiber laser machine

Souce: banglemark.com

To ensure the longevity of the machine, you should always keep it in a cool, clean room. Never put any objects that are not the part of the machine onto it, and cover it with the appropriate dust protection.

Make sure to let the machine cool off properly between uses, and don’t leave it plugged in when you’re not using it. Also, your safety and the safety of the personnel operating the machine should be your first priority. Always make sure to wear eye protection when operating the machine and avoid talking during the process. Other than that, make sure that the laser never comes into contact with the skin, since it could lead to serious burns and injury. Keep a fire extinguisher close by, and don’t let people with pacers near the machine since it could disrupt the efficiency of the pacer.

The takeaway

Fiber laser machines are a great piece of equipment to have, but you need to ensure you’re well prepared to operate it safely. Make sure to buy the machine from a trusted supplier, and learn how to properly maintain it. Always remember that the manual is your best friend, and make sure to contact your supplier if anything unusual happens to the machine. All in all, as long as you follow the operating manual, the newly acquired fiber laser machine should not pose any problems whatsoever.