It has a strange name, and to the less skilled in mechanics, it may seem a bit strange looking like an alien tool. However, a good mechanic cannot do without it.

Yes, because although it may seem strange to you, that I have heard this from more than one, the screws are not tightened until you can no longer or until it occurs to you. Screws, nuts, and other threaded parts have to be tightened to what is called their torque.

It is a torque (the tightening against the resistance of the bolt or nut) and, therefore, it is expressed in units of force per turning distance. It is usual, therefore, to find that the tightening torques come in NM (Newton per meter), Kgf-m (Kilograms force per meter), and even in some cases in English measurements such as Lbs-ft (Pounds per foot) or Lbs- in (pounds per inch).

Table of Contents

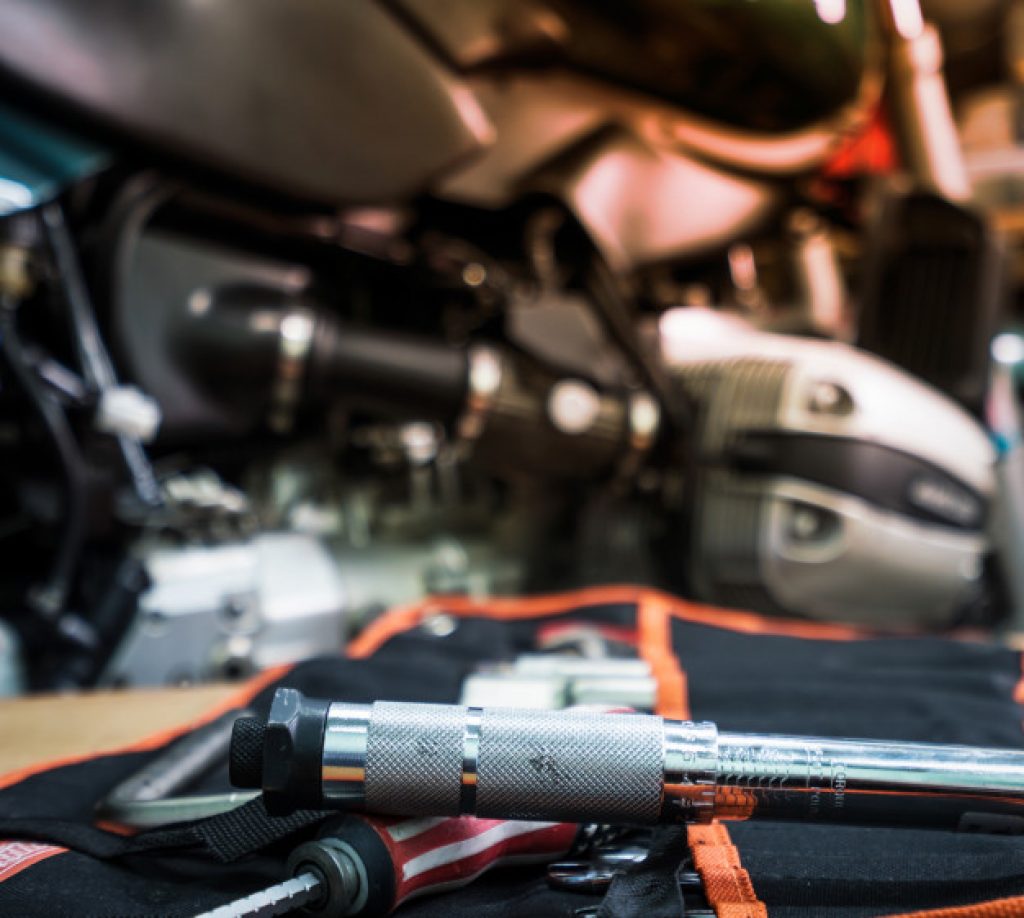

The torque wrench

Source: freepik.com

This is the generic name of the tools with which you can measure that torque. They can be of many types, although the most common (and recommended) are the ratchet type that you can regulate the desired tightening and the wrench “pops” when it reaches the tightening. Normally that “jump” is a “clack” that sounds and notes in the hand and it is the moment when the screw is already tightened. They are usually regulated on the handle itself.

Others, also very reliable, have a scale on the head and as you press, they mark the tightening. When you reach the desired torque, you stop squeezing, without further complication. The normal thing is that they are long, of about 50 cm at least, to be able to make more leverage and with more precision. For motorcycles, it is best to choose a wrench with a torque range of 0 to 210 Nm or 21 Kgfm. The tightening torque is essential, each screw/nut has its own and depends basically on its function, the length of the screw, and its diameter. In the motorcycle workshop manual there is usually a table with the torque for each bolt/nut.

When buying it, check that the square that serves as a support for the glasses (mouths to catch the screw or nut) is the size of your normal ratchet. If not, you will have to buy new glasses or, at least, an adapter. There are many measures of this square, but the most used are 1/2 “, 3/8”, and 1/4 “. For a motorcycle the normal thing is that for almost all the nuts/bolts there are 3/8 ”sockets, it is the most generic. Do not buy three dynamometers either, one for each measurement: we can buy the 1/2 ”torque and use a 3/8” adapter or vice versa. The size of the socket on the socket depends on the tightening torque that the dynamometer supports, a 12 mm socket for a 1/4 ”wrench will not reach 210 Nm, because it is designed for small tightening. To help you, here is the Torque Wrench Center.

Tightening

Source: freepik.com

Logically, it is important that the nuts of the motorcycle are tight. However, and contrary to what many believe, it is not good to squeeze everything you catch “to death”: a cylinder head, for example, has to be perfectly flat, with the same pressure on the gasket and the block around its entire contour. If not, it can end up deforming and appearing compression leaks or mixing the oil and water inside the engine, with the consequent “destruction”. For this, it is not only important to tighten with the correct force indicated by the manufacturer, but also to follow the order that they send you. If there is no established order, always cross: if you start with a screw, the next to tighten is not the one next to it, but the one in front. Follow with the one you have at an angle to that and then the one in front of this third.

The truth is that many mechanics have a bad habit of using the dynamometer only on the cylinder heads, blocks, and little else: true, here it is very important. But if you take the workshop book you will see that almost all the threads of the motorcycle have their tightening and it is like that, with all of them “in place” as the motorcycle will last longer and will work better: there are no more tightening that cause friction.

The head of the glass

Source: freepik.com

The next thing when choosing a torque wrench is to choose the head of the socket, there are many sizes but the most used are 1/2 ”, 3/8”, and 1/4 ”.

They are the elements that are attached to the dynamometer and allow you to tighten. We must therefore choose the head for the dynamometer, for a motorcycle, the normal thing is that almost all the nuts/bolts are for 3/8 ”sockets, it is the most generic. We can always buy the 1/2 “torque and use a 3/8” adapter or vice versa.

The size of the socket head is a function of the tightening torque that the dynamometer supports, a 1/4 ”wrench will not reach 210 Nm because it is designed for small tightening. The first thing to know to tighten or retighten is that the bolt/nut is first loosened and then tightened to the desired torque.

It is always tightened when cold, due to the expansion of the hot materials. The key at the moment of the requested torque makes a “clack” and at that moment you must stop, if you continue you will go up in torque. It is important to make the gesture continuous at the moment of tightening, that is why it is necessary to use turns and elbows where the complete turn of the key does not allow us.

In cases of non-use for a long time, it is advisable to store it with the minimum possible torque, turning the grip counterclockwise as far as it will go. The time dedicated to tightening the bolts of a motorcycle is high, for that reason and because it is almost impossible to have all the models and pairs for each motorcycle, that is why these tasks are not carried out correctly in the workshops. Responsible use of this tool will provide us with great security in the mechanics of our motorcycle.