Welcome, machine operators, to your go-to guide for PTO troubleshooting!

PTO, or Power Take-Off, can sometimes be a tricky beast. But don’t worry, we’ve got you covered. We’ve rounded up the top tips to make your PTO problems a thing of the past.

So gear up for some easy-to-understand advice that will keep your machines running smoothly and efficiently. Let’s dive right in!

Table of Contents

Prioritizing Regular Maintenance

One cannot overstate the importance of regular maintenance in ensuring the long-term health and optimal performance of your machinery’s Power Take-Off. It’s akin to a well-balanced diet and routine workout for maintaining one’s health.

Regular maintenance helps identify potential issues early, avoid unexpected breakdowns, and extend the equipment’s overall lifespan. Consider it as your first line of defense against any PTO problems you might encounter.

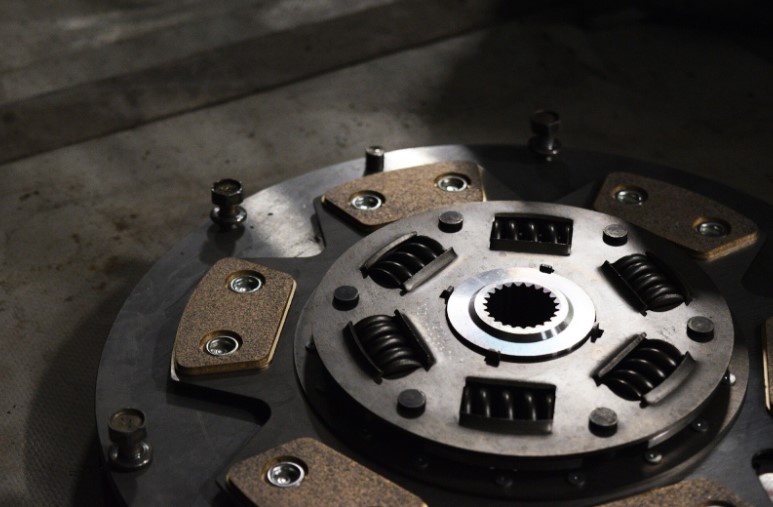

You should also make sure to use high-quality equipment like this PTO clutch for SCAG tiger cub series. Well-maintained machines and equipment run smoother, perform better, and are less likely to give you headaches down the line.

Spotting the Issue

Identifying issues with your Power Take-Off at an early stage is crucial for electric PTO clutch troubleshooting. Keep a watchful eye for any signs of trouble, such as unusual noises, vibrations, or decreased performance.

Always remember, that any abrupt deviation from normal operation is a potential red flag and should be investigated promptly. Close attention to such details can save you a substantial amount of time and resources in the long run. This practice allows you to tackle issues before they can escalate and cause severe damage to your machinery.

Check for Loose or Worn Parts

In the course of operating machinery, loose or worn parts are some of the most common culprits behind symptoms of bad PTO clutch. Regular inspection of the machinery’s components is vital to detect wear and tear or parts that may have loosened over time. Keep in mind that even a small, unnoticed loose nut or bolt can lead to significant operational issues down the line.

Replacing worn-out parts promptly and tightening loose ones can significantly reduce the risk of unexpected machinery breakdown and ensure the smooth functioning of your Power Take-Off system. This step might seem trivial, but it’s a key aspect of effective PTO troubleshooting.

Make Sure Things Line Up Right

When dealing with Power Take-Off systems, proper alignment of machinery components is key. This means ensuring that the drive shaft and the equipment it powers align correctly. Misalignment can lead to excessive wear and tear. This causes the PTO system to underperform or malfunction.

Regularly checking for alignment and making necessary adjustments can significantly enhance the performance and longevity of your machinery. Remember, every component needs to be “in line” for the system to work optimally.

Learn More About PTO Troubleshooting

All right, folks, we hope this guide has given you the know-how to tackle PTO problems head-on. Always remember, taking care of little things can help your machines stay in top shape.

So, keep your machinery happy, and they’ll keep you happy by doing their job right. Keep on trucking, machine operators!

If you want to explore the best topics aside from this PTO troubleshooting, we’ve got you covered. Check out some of our other blogs today!