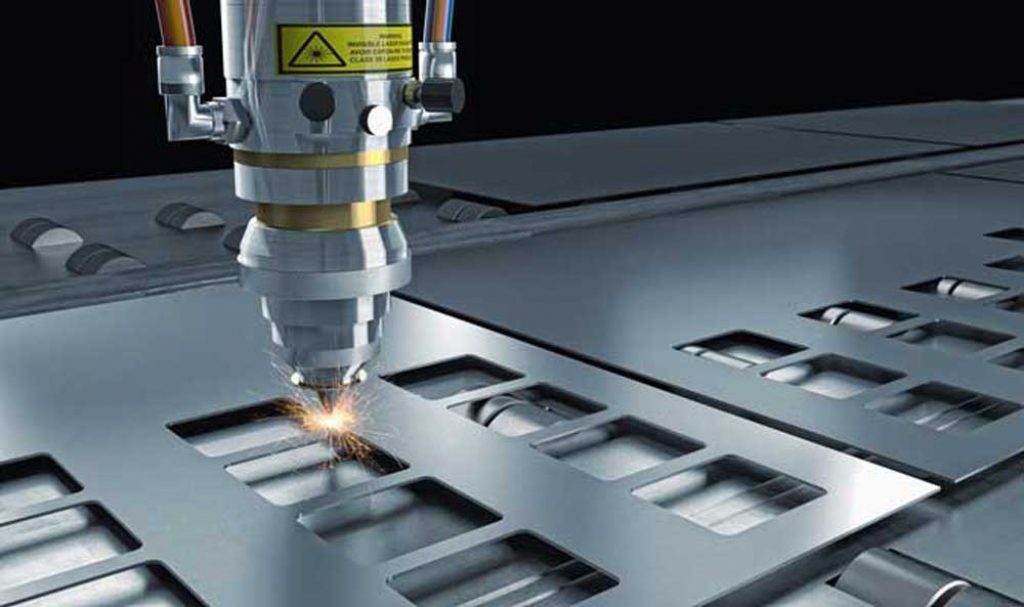

Purchasing your first laser cutter is not an easy task, but it can be if you know the right things before finalizing your transaction. Today we’re here to help you learn some more about it, so if you are looking to make such a purchase shortly, this is the right place to be.

You see, laser cutters are quite complicated devices, and they’re still considered to be relatively new in the consumer world. They’re not very easy to work with unless you know what you’re doing, and most of them are considered to be dangerous for people who lack the basic training. But, technology is constantly evolving and everything is working in the favor of the average consumer.

Devices such as laser cutters are becoming more “user-friendly”, easier to use, less expensive and the model variety is broader than ever. You are no longer limited by being offered just a few models to choose from. Today, we have many brands manufacturing such tools, so you’re free to take your time and make the right decision that you won’t regret later on. Here’s what you need to know when it comes to purchasing your first laser cutter in 2024.

Table of Contents

1. Define your need for a cutter

Source: dsbaltic.com

The laser cutter is used to cut things precisely in a short amount of time, without too much effort. But, this isn’t narrow enough. People buy these tools to cut different things, meaning different materials, and this is where you need to be a bit more specific. You can start by defining what exactly you need your cutter for. Then, when you come to a strong conclusion, it’s time to choose based on that.

You can try to do a bit of research on which lasers are optimal for certain tasks, or if that doesn’t work for you, you can contact some of the employees at the company you want to purchase from. They’ll be more than glad to help you make the right choice.

2. Measure the air humidity of your area

Source: precitec.com

We’re not sure whether many people know about this, but the air humidity in your area has a lot to do with the use of your brand-new laser cutter. If you live in a country that has a lot less air humidity than let’s say Malaysia, you’ll need an entirely different air compressing system for your device.

This has a lot to do with your future options because it might be a bit difficult to sell it to people who live in a country with different air humidity. But, if you are planning to make this a permanent investment for your company or business, you shouldn’t think about re-selling it after. However, keep it in mind. Dx Tech is a website where you can get informed about co2 laser marking machines and a few other comparisons that you might be interested in. You can also Google the statistics for the air humidity in your area, or if you are purchasing from a very reputable manufacturer, they might have their chart and send you a compressor based on that, specific for your country.

3. Do your research on compressors

Source: bandwidthuae.com

It’s important to do some background research on compressors before you purchase a laser cutter in 2024. What type of a compressor you need with your laser cutter will depend on both the size and the strength, or power, of the laser. Some lasers are 60W while others are up to 200W or even more than that. Usually, the company that you’ll purchase from will send a professional technician to help you set everything up.

Depending on the company, this should include setting up the suction port, the water drainage, whether automatic or not, as well as the air compressor. It may or may not be included in the price, which is why we recommend that you do quite a lot of research before choosing your manufacturer. If you are buying from overseas and you expect delivery, make sure that you are very clear about the air humidity in your country. They’ll need to send a completely different model based on this.

4. Consider an automatic water drainage

Source: pwjet.com

Depending on how much work you’re willing to do with your laser cutter, you should be emptying your water canister quite regularly, sometimes even multiple times daily. When you are using your device in a country that has very high air humidity, the compressor will end up exhaling significant amounts of water, and the tank will easily get filled.

If you are busy with work and you want to avoid being interrupted all the time, investing in an automatic water drainage system is a great choice. This will empty the water tank on its own and allow you to focus on what’s important instead. It’s not something that’s 100% necessary, but it sure does make life a lot easier. Keep in mind that this will add up to the price, but not too much.

5. You’ll need a honeycomb

Source: wayofwood.com

Once again, this is something that you’ll need to decide based on the type of work you’ll do with your laser cutter. If you work with larger objects, then you can skip this step as it might not be required for your particular situation. However, if you work with a smaller object, purchasing honeycombs can be a real lifesaver. These little combs are used to protect the smaller items from falling to the bottom after being cut out by your device. Also, it prevents the head of your laser to be damaged by them when something like this happens. Just keep it in mind because it can be very useful for certain scenarios.

Extra: Pay attention to your materials

We decided to include this as an extra tip, which is very important for the overall experience you get with your laser cutter tool. Try to use only top-quality materials from reputable providers if you want to have the smoothest experience. It might cost more, but all of your products will end up being very valuable. If you are working with wood, for example, try to find a reputable and reliable provider, instead of purchasing the cheap factory-made materials.