Cannabis manufacturing is the process of producing a wide range of cannabis-based products, including edibles, topicals, tinctures, and concentrates. With the growing demand for cannabis products, it is essential to understand the various stages involved in the production of these products, from cultivation to packaging, and labeling. In this blog post, we will provide an overview of the cannabis manufacturing process, as well as the technologies and techniques involved in each stage.

Table of Contents

Cultivation of Cannabis Plants

The cultivation of cannabis plants is the first step in the manufacturing process. There are two main types of cannabis cultivation: outdoor and indoor.

Outdoor cultivation involves growing cannabis plants in a natural environment, while indoor cultivation involves growing cannabis plants in a controlled environment, such as a greenhouse or a grow room.

Source: chatelaine.com

The success of cannabis cultivation depends on several factors, including climate and weather, light and water, and soil and nutrient management. The right combination of these factors will ensure that the plants grow healthy and produce high-quality buds.

Once the cannabis plants have reached maturity, they are harvested and dried. This is an important step in the manufacturing process, as it affects the potency and quality of the final product. The drying process should be done slowly and carefully to ensure that the buds retain their potency and flavor.

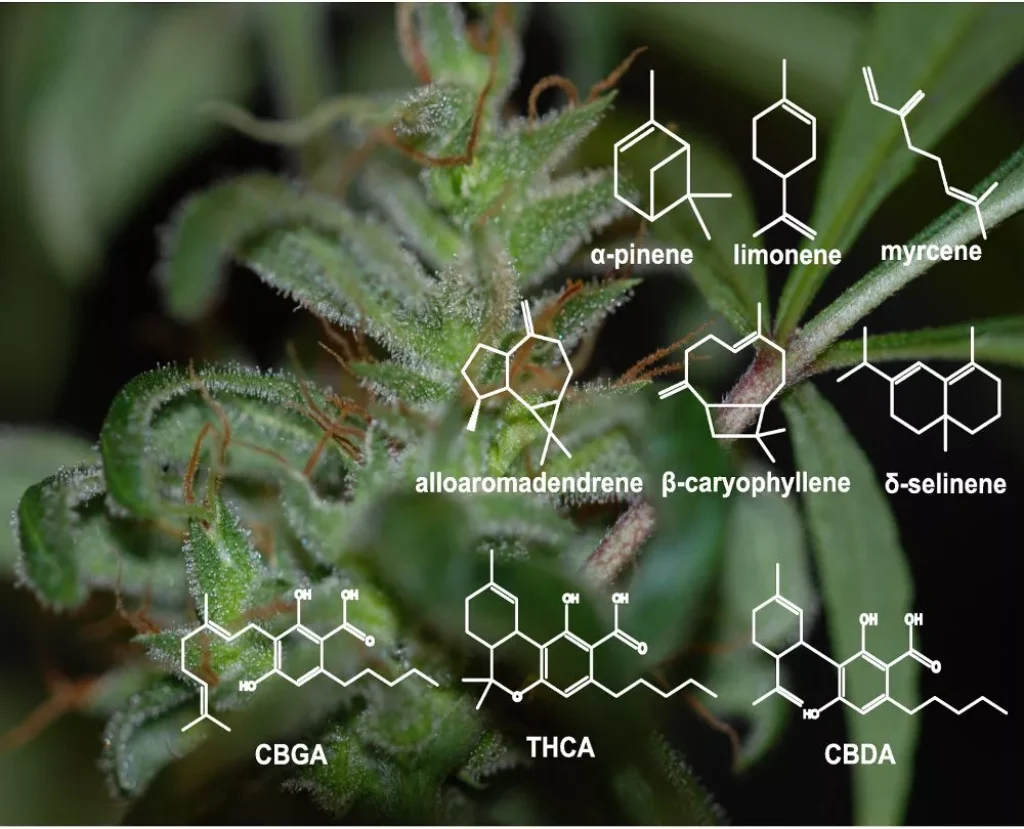

Extraction of Cannabinoids and Terpenes

Source: groweriq.ca

This is a crucial step in the cannabis manufacturing process to craft products such as tinctures, vapes, and edibles. There are several extraction methods that can be used. Here are some of the most commonly used:

Solvent Extraction

Solvent extraction is the most popular method for extracting cannabinoids and terpenes from cannabis. In this method, a solvent is used to dissolve the cannabinoids and terpenes from the dried buds. The solvent is then evaporated, leaving behind a concentrated extract. There are two main types of solvent extraction: ethanol or butane extraction and water-as-solvent extraction.

Mechanical Extraction

Extracting cannabinoids and terpenes from cannabis through mechanical means, such as grinding or sieving, is referred to as mechanical extraction.

Rosin Press Extraction

Source: fedequipblog.fedequip.com

The process of using heat and pressure on dried cannabis buds to extract cannabinoids and terpenes is known as rosin press extraction.

Quality control is an essential part of the extraction process. The extracted material should be carefully tested and analyzed to ensure that it meets the required standards and regulations.

Once the extract has been obtained, it is purified and concentrated to produce a final product that is ready for formulation and infusion.

Formulation and Infusion of Cannabis Products

The formulation and infusion of cannabis products are the next steps in the manufacturing process. There are several types of cannabis products, including edibles, topicals, tinctures, and concentrates. Each type of product requires a different formulation and infusion technique.

- Formulation Techniques – Formulation techniques such as homogenization, emulsification, and microencapsulation are used to produce consistent and stable cannabis products. These techniques ensure that the products have the desired texture, flavor, and potency.

- Infusion Techniques – Infusion techniques include hot infusion, cold infusion, and slow cooker infusion to incorporate the extracted cannabinoids and terpenes into the final product. Each infusion technique has its own advantages and disadvantages, and the choice of technique will depend on the type of product being produced.

Several cannabis product maker companies also use specialized equipment to extract and infuse cannabis products. These include ultrasonic homogenizers, volumetric filling machines, and tablet presses. All of these pieces of equipment enable the manufacturer to efficiently produce a variety of cannabis products with very precise levels of potency.

Packaging and Labeling of Cannabis Products

Source: manzurilaw.com

Packaging and labeling are the final steps in the cannabis manufacturing process. There are strict packaging requirements and regulations that must be followed, including the use of child-resistant packaging and barrier packaging to protect the product, and ensure the safety of consumers.

Labeling requirements and regulations are also strict and include the inclusion of health and safety information, dosage information, and an ingredient list. It is essential to ensure that the labeling is accurate and meets all state regulatory requirements.

Quality Control and Compliance in Cannabis Manufacturing

Good manufacturing practices (GMP) must be followed to ensure that the products are safe and of high-quality. Regular testing and analysis of the products, including pesticide testing, microbial testing, and cannabinoid potency testing, must be conducted to ensure that the products meet the required standards and regulations.

The cannabis manufacturing process must be in compliance with federal and state regulations. This can be obtaining the necessary licenses and permits, following the correct procedures for extraction and formulation, and adhering to strict labeling and packaging requirements.

Cannabis manufacturing is a complex process that involves several stages, including cultivation, extraction, formulation, and packaging. Each stage requires specific technologies and techniques to produce high-quality and safe cannabis products.

Always ensure that the manufacturing process is carried out with quality control and compliance in mind. They should be following good manufacturing practices, conducting regular testing and analysis of the products, and adhering to federal and state regulations.

As the cannabis industry continues to grow, it is expected that new technologies and techniques will be developed to improve the quality and efficiency of the manufacturing process. The importance of quality control and compliance in cannabis manufacturing cannot be overstated, as it ensures that consumers receive safe and high-quality products.