Wholesale suppliers are the unsung heroes of countless industries. From the smartphone in your hand to the shoes on your feet, wholesale suppliers play a pivotal role in bringing products to market. For businesses, understanding the intricacies of their operations isn’t just beneficial—it’s essential. This article delves deep into the world of wholesale suppliers, offering insights that can help businesses make informed decisions and foster successful partnerships.

Table of Contents

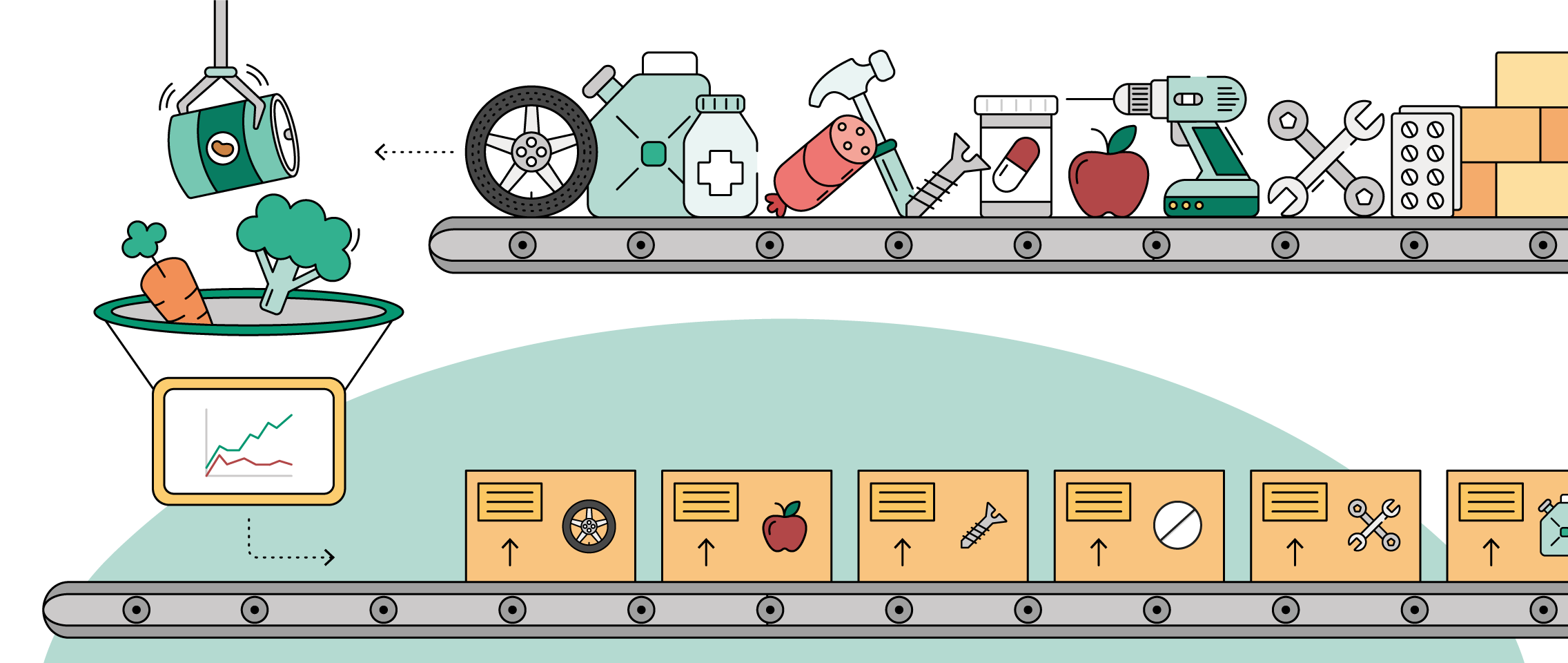

Types of Wholesale Suppliers

Source: ordercircle.com

The wholesale landscape is vast and varied. Here’s a breakdown of the primary types:

Manufacturers: These entities produce goods from raw materials. For instance, a tech company manufacturing smartphones or a fashion brand producing clothing.

Distributors: They buy products directly from manufacturers and sell them to retailers or other businesses. They often have a vast network and can handle large volumes, making them ideal for businesses looking to scale.

Importers: These are businesses that source products from foreign manufacturers and bring them into a domestic market. They handle customs, tariffs, and other import-related logistics.

Dropshippers: A more modern addition, dropshippers hold no inventory. Instead, they transfer customer orders directly to manufacturers or other suppliers, who then ship the products to the customers.

Each type has its unique role. For instance, while manufacturers are crucial for bespoke product needs, distributors can offer a range of products from various sources. Understanding these nuances is key to determining the right fit for your business.

Key Operations of Wholesale Suppliers

Suppliers wholesale are more than just middlemen. Their operations are intricate:

Sourcing: This involves finding and procuring raw materials or products. It’s a delicate balance of cost, quality, and reliability.

Inventory Management: Effective stock control ensures that products are available when needed, minimizing storage costs and preventing stockouts.

Distribution: This is the process of getting products to retailers or end-users. It requires a robust logistics network and can significantly impact product pricing and availability.

Each operation is a cog in the supply chain machine. A hiccup in sourcing can lead to inventory shortages, while distribution inefficiencies can increase product lead times. For businesses, understanding these operations can lead to better forecasting, pricing, and overall strategy.

Factors to Consider When Choosing a Wholesale Supplier

Source: cms.proqura.com

Selecting the right supplier is a blend of art and science. Key considerations include:

Reliability: Can they consistently meet your needs?

Pricing: Are their prices competitive, and do they offer volume discounts?

Product Quality: Are the products up to your standards?

Location: Proximity can impact shipping times and costs.

It’s not just about numbers. Visiting a supplier’s facilities, checking references, and even placing trial orders can offer invaluable insights.

The Supplier-Business Relationship

A transactional relationship with suppliers is passé. Today, the emphasis is on partnership. Building a strong rapport with suppliers can lead to:

Better terms of payment.

First access to new products or innovations.

Joint marketing or promotional ventures.

Effective communication is the bedrock of this relationship. Regular check-ins, feedback loops, and transparency can foster trust and mutual growth.

Evaluating Supplier Performance

Source: spendmatters-site.s3.amazonaws.com

Performance metrics are crucial. Key criteria include:

On-time Delivery: Are products delivered as promised?

Order Accuracy: Are shipments correct and undamaged?

Responsiveness: How quickly do they address concerns or issues?

Regular evaluations can identify areas of improvement, ensuring that the supplier relationship remains beneficial.

Industry Best Practices

Working with suppliers is an art that varies across industries. For instance:

In fashion, it’s common to have multiple suppliers for different product lines, ensuring diversification.

Tech companies often engage in joint R&D with suppliers to co-create innovative products.

Understanding and adopting these best practices can give businesses a competitive edge.

Navigating Challenges in Supplier Partnerships

Source: www.supplychainbrain.com

Challenges are inevitable. Demand fluctuations can lead to stockouts or overstock. Quality control issues can tarnish a brand’s reputation. Changing market dynamics, like new tariffs, can impact costs.

Overcoming these challenges requires agility and collaboration. Open communication, contingency planning, and regular strategy sessions with suppliers can help navigate these waters, ensuring that the partnership remains fruitful even in turbulent times.