Expanded metal is a versatile material made by making multiple slits in a metal sheet and then stretching it to create a unique diamond-shaped pattern.

This process results in a mesh-like structure that is lightweight yet sturdy. The manufacturing of expanded metal does not involve any material waste, making it an environmentally friendly choice. The metal’s expansion creates a greater surface area, providing numerous functional benefits such as improved grip and increased air circulation.

The structural integrity of expanded metal allows it to be used in a variety of applications, from industrial walkways and security fences to decorative interior design elements and architectural accents. It can be made from various metals, including aluminum, steel, and copper to meet diverse needs in terms of strength, corrosion resistance, and aesthetic appeal. With its ability to combine function with form, expanded metal is a valuable material in both construction and manufacturing sectors.

Due to its distinctive fabrication process, expanded metal offers superior durability and security over traditional metal sheets.

Its open design facilitates the efficient passage of light, heat, and sound, while simultaneously providing a barrier to entry. This makes it particularly beneficial for enclosures, protection screens, and ventilation systems. Its adaptability is further underscored by the range of patterns and gauges available, enabling customization for specific project requirements.

Table of Contents

Basics of Expanded Metal

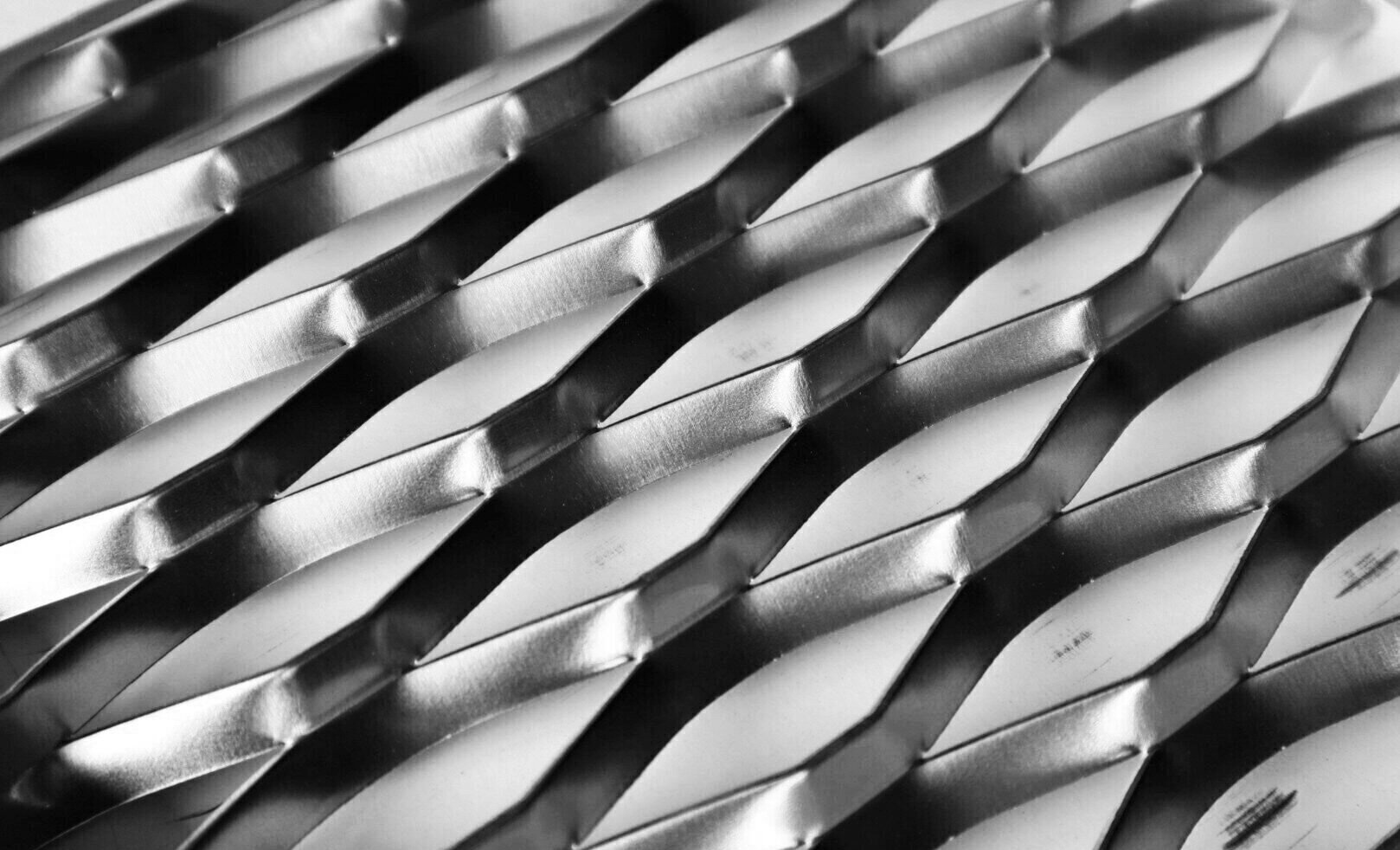

Source: prmetals.com

Expanded metal is a versatile material made by cutting and stretching metal sheets to create a mesh-like pattern. The result is a strong, lightweight product used in various applications, from industrial to architectural.

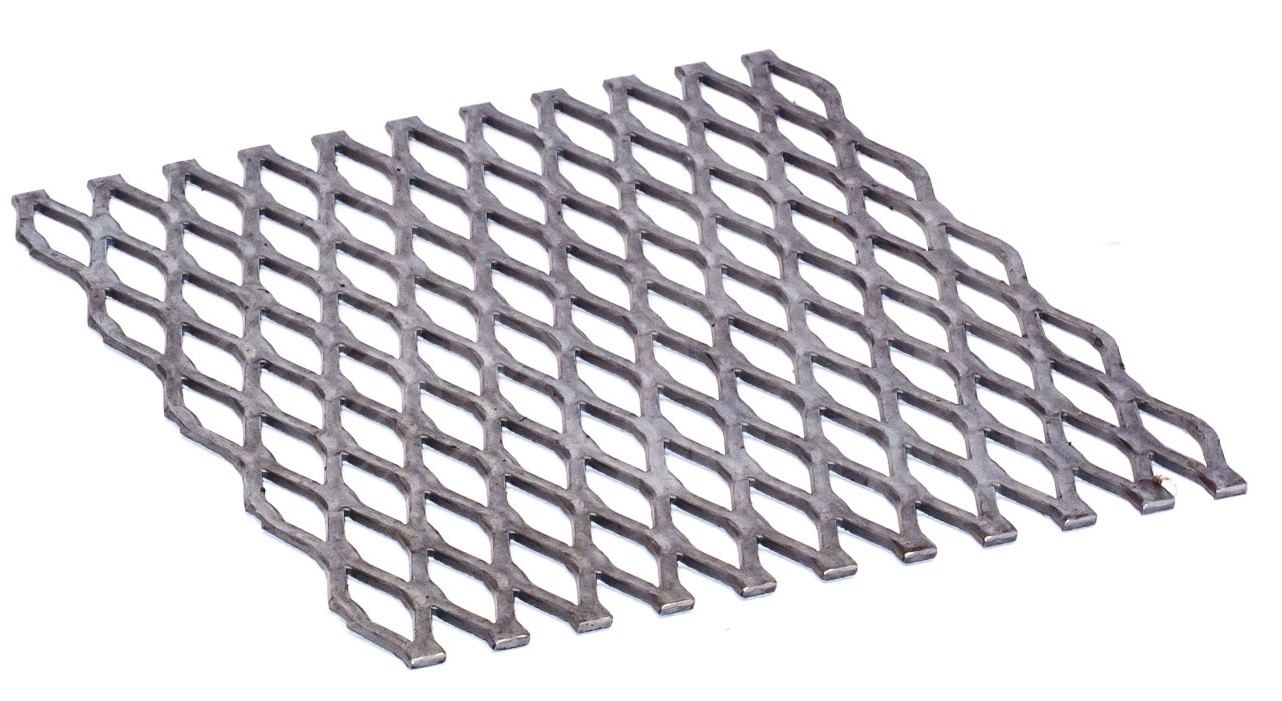

Manufacturing Process

The manufacturing process of expanded metal involves a precision-cutting and stretching method that turns solid metal sheets into an expanded mesh. The metal sheet passes through an expanding machine where a specialized knife cuts a series of slits. The machine then stretches the cut material, forming the characteristic diamond-shaped gaps, termed “diamonds,” with remaining metal strands.

Materials Used

Various metals can be used to produce expanded metal, which includes but is not limited to:

- Aluminum: Lightweight and corrosion-resistant, ideal for architectural applications.

- Steel: Offers strength and durability; often used in construction and industrial sectors.

Other materials such as stainless steel, titanium, and copper are also utilized based on the specific properties required for the application, like resistance to corrosion, strength-to-weight ratio, and electrical conductivity.

Properties and Characteristics

Expanded metal possesses distinct properties that make it suitable for a variety of applications in industrial, architectural, and security settings.

Strength and Durability

Source: medium.com

Expanded metal is produced by cutting and stretching a solid metal sheet, resulting in a strong and durable mesh.

The uncut knuckles of expanded metal withstand stress and resist impacts. Its one-piece construction means there are no weak points caused by welds or joints, enhancing its strength and longevity.

Weight and Flexibility

Despite its strength, expanded metal is lightweight due to its mesh-like structure. The ratio of open area to metal used provides a balance between weight and structural integrity.

This property allows for ease of handling and installation. Flexibility can vary depending on the thickness of the original metal sheet and the size of the diamond-shaped openings. Thin sheets offer higher flexibility, making them suitable for applications requiring contouring and bending.

Air Flow and Filtration

Source: en.wikipedia.org

The open area of expanded metal permits the passage of air, fluid, and light, making it an excellent material for applications requiring ventilation or filtration.

The size of the openings can be customized to accommodate specific flow rates and particle sizes. This characteristic is quantifiable and can be used to specify the right expanded metal type for filtration systems, vents, and grilles.

Applications of Expanded Metal

Expanded metal has diverse applications in various fields due to its strength, versatility, and cost-effectiveness. It serves a critical role from supporting architectural aesthetics to ensuring security measures.

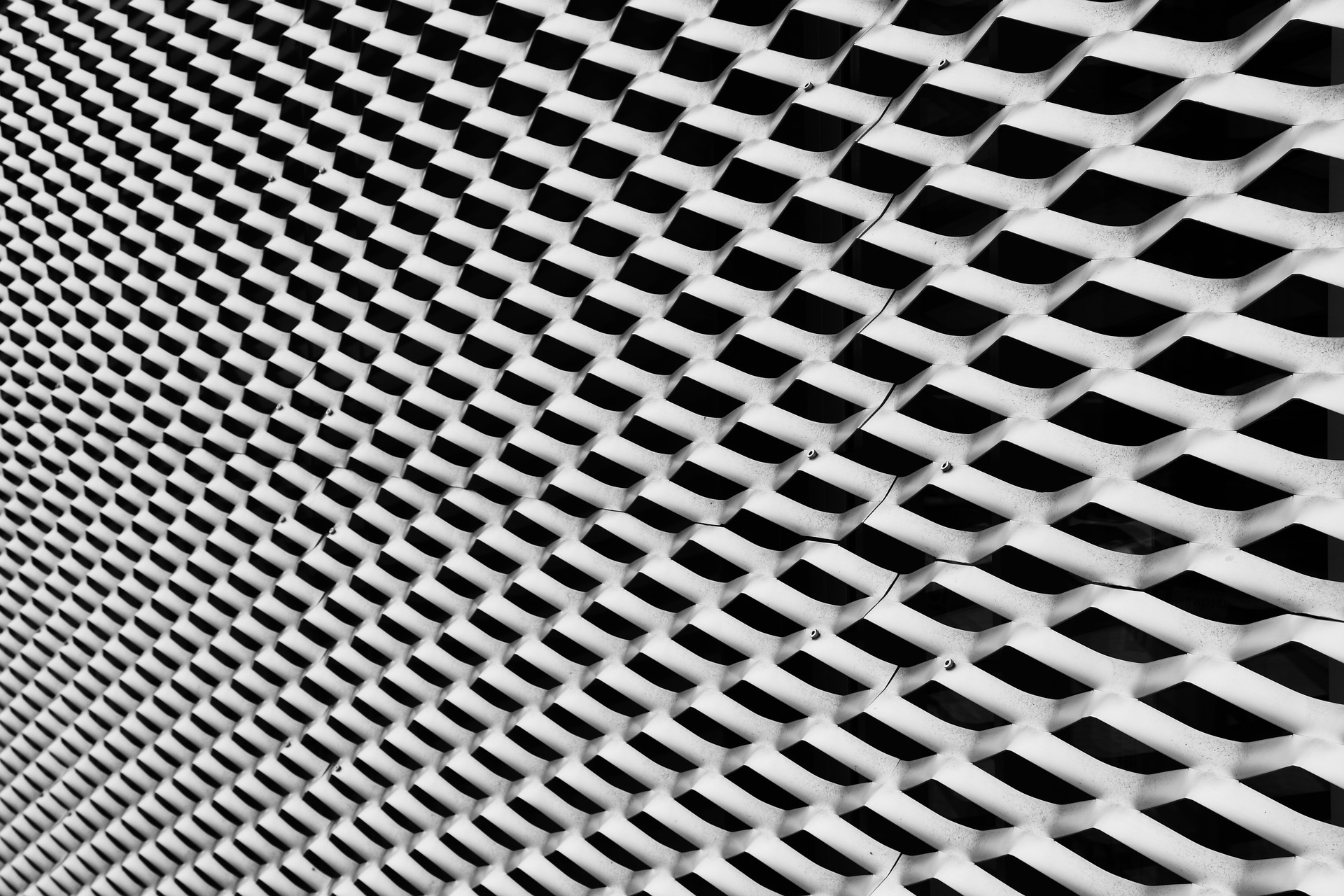

Architectural Design

Source: bestalmetal.com

In architecture, expanded metal is utilized for its unique texture and ability to control light and air flow.

Specific uses include:

- Facade cladding: Durability and ventilation

- Interior design elements: Aesthetic appeal and functional purposes like room dividers

Industrial Uses

The industrial sector takes advantage of expanded metal for practical and safety reasons.

It is commonly found in:

- Walkways and catwalks: For slip resistance and support

- Machinery guards: To protect workers from moving parts

Security and Fencing

Source: marcospecialtysteel.com

Expanded metal provides robust security solutions. It is employed in various security applications including:

- Fencing for residential and industrial areas: Effective deterrent against trespassing

- Secure enclosures: For machinery or sensitive areas, ensuring restricted access

Standards and Specifications

Expanded metal is governed by a variety of standards and specifications, ensuring that it meets certain quality and performance criteria. These are defined by national and international bodies to standardize dimensions, materials, and strength.

The most commonly referenced standards include:

- ASTM F1267: Specification for Metal, Expanded, Steel.

- ISO 3310-1: International standard for Test Sieves – Technical Requirements and Testing.

These documents detail important parameters, such as:

- Thickness: The base metal thickness, prior to expansion.

- Strand Width: Width of the metal strips or “strands” that make up the diamond-shaped openings.

- SWD/LWD: Short Way Diamond / Long Way Diamond, indicating the dimensions of the openings.

Manufacturers and users must adhere to these standards to ensure that expanded metal products are fit for purpose and are of consistent quality. Specific industrial sectors might have additional requirements that dictate the use of certain materials or finishes:

- Construction: May require galvanized steel for corrosion resistance.

- Manufacturing: Often specified to be made from aluminum for its lightweight properties.

Here are some additional considerations outlined in the specifications:

- Tolerances: Acceptable variations in dimensions and size.

- Load Performance: Metrics for bearing weight and pressure.

- Material Quality: Standards for the raw materials used to produce expanded metal.

These specifications are critical for buyers to ensure the expanded metal meets the desired performance and safety standards. They also guide manufacturers in production to maintain quality control.

Buying Guide

Source: leonfuat.com.my

When purchasing expanded metal, buyers should focus on quality, supplier reliability, and cost efficiency. This guide assists in making informed decisions by evaluating these critical aspects.

Evaluating Quality

- Material Composition:

It is essential to assess the type of metal used. Common materials include aluminum, steel, and stainless steel. Each has different strengths and is suitable for specific applications. Inspect the metal’s thickness and strand width, which determine its durability and support capacity.

- Mesh Size:

Mesh size dictates airflow and light penetration. Smaller openings suit fine filtration, while larger ones are for substantial materials retention.

Sourcing Suppliers

- Reputation: Research supplier history and client testimonials. Also assess the consistency of product quality they have delivered over time.

- Certifications: Look for suppliers with industry-recognized certifications, verifying adherence to quality and safety standards.

Geographical Location:

The proximity can affect lead times and shipping costs. Local suppliers might offer better after-sales support.

Cost Considerations

Price Breakdown: Material cost, fabrication and finish costs and shipping or delivery expenses.

Inquire about hidden costs such as customizations or additional services. Many suppliers provide scaled discounts for bulk purchases, but evaluate if the reduced cost per unit justifies the larger upfront investment.