Surface finishing plays a crucial role in the performance, durability, and appearance of components across a wide range of industries.

From automotive restoration to aerospace engineering, the ability to clean, smooth, or refresh a material’s surface without compromising its structural integrity is essential.

Among the many surface treatment methods available today, vapour blasting has become increasingly valued for its gentle yet highly effective approach.

This wet-based process, also known as wet blasting, combines fine abrasive media with water to produce a controlled, slurry-based cleaning action that offers a distinct set of advantages over dry blasting and other traditional techniques.

The use of a vapour blasting machine has grown steadily as companies seek methods that minimise dust, reduce material removal, and deliver a uniform, refined finish suitable for both functional and cosmetic purposes.

Table of Contents

How Vapour Blasting Works

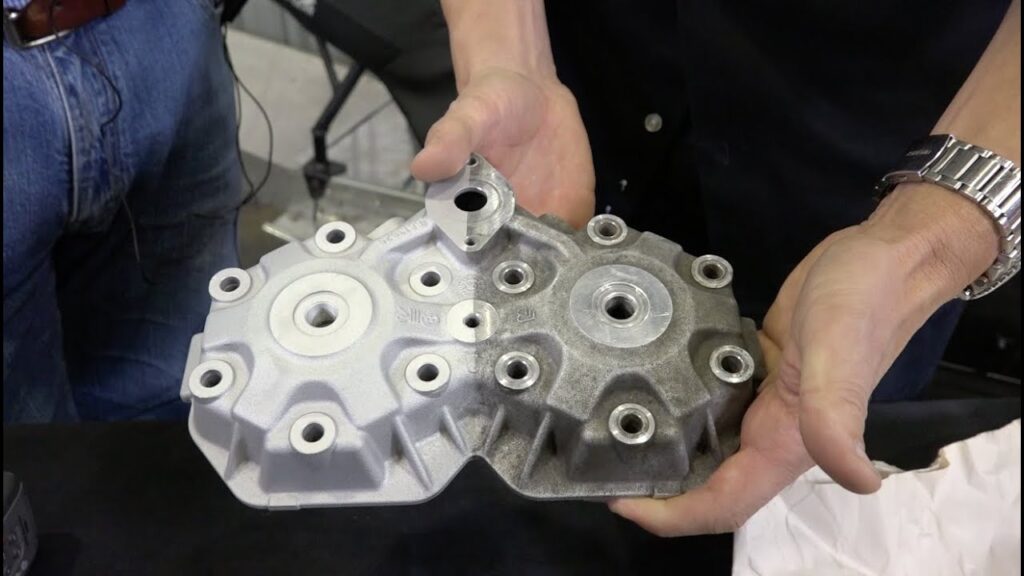

Source: youtube.com

Vapour blasting uses a mixture of water and abrasive particles, often referred to as a slurry, which is propelled at the surface of the component under controlled pressure.

The presence of water serves several purposes. It cushions the abrasive, creating a softer impact that prevents aggressive cutting, and it helps disperse heat, reducing the likelihood of surface distortion.

The water also traps particles, dramatically reducing airborne dust and creating a cleaner, more manageable working environment.

Unlike dry blasting, which relies on high-velocity abrasive impact, vapour blasting depends on the lubricating and flushing action of the slurry.

This allows contaminants such as oxidation, grime, old coatings, or machining marks to be removed without damaging the base material.

The result is a cleaner, smoother surface that retains its dimensional accuracy.

Key Advantages of Vapour Blasting

Minimal Material Removal

One of the most significant benefits of vapour blasting is its gentle action. The cushioning effect of water reduces the abrasive’s cutting force, making the process ideal for components that must maintain exact tolerances.

This is particularly valuable when treating engine casings, delicate alloy parts, or vintage components where preserving originality is essential.

Superior Surface Finish

The slurry-based technique produces a consistent, satin-like finish that is both attractive and functional. It can improve surface uniformity, reduce roughness, and create a texture that helps coatings or sealants adhere more effectively.

For industries where aesthetics matter, such as classic car restoration or high-end manufacturing, vapour blasting offers a reliable way to enhance appearance without introducing harsh abrasions.

Reduced Dust and Contamination

Dry blasting methods can produce large amounts of dust, which can pose health risks and require extensive cleaning.

In vapour blasting, the water traps particulates at the point of impact, significantly reducing dust generation.

This leads to a cleaner workspace, lower health risks, and a reduced likelihood of contaminants adhering to the treated surface.

Versatility Across Materials

The process is suitable for a wide range of materials, including aluminium, stainless steel, titanium, brass, and various composite materials.

It can handle delicate surfaces without causing peening or warping, making it a versatile choice across engineering, manufacturing, and restoration fields.

Common Applications of Vapour Blasting

Automotive and Motorcycle Restoration

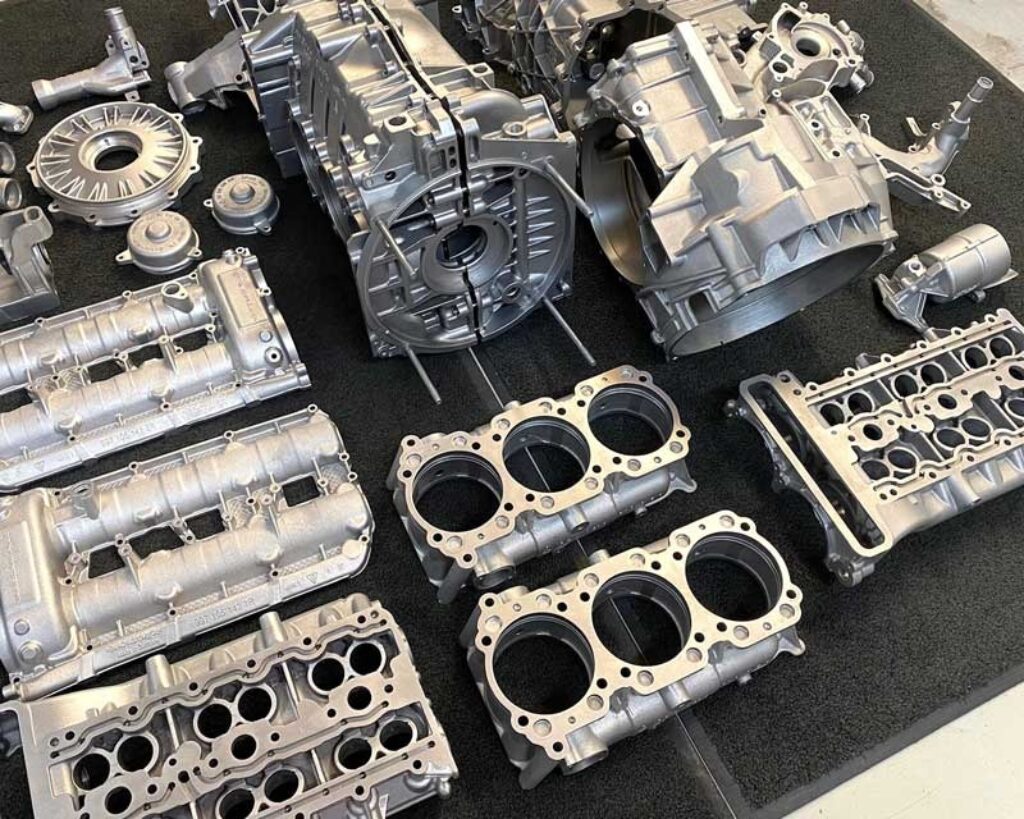

Source: vapourblastservices.co.uk

Vapour blasting is frequently used to restore metal components such as engine heads, carburettors, gearbox casings, and brake parts.

The process removes years of grime and oxidation while preserving original cast textures.

It is especially valued in classic and performance vehicle communities, where maintaining authenticity is as important as achieving a clean finish.

Aerospace and Engineering

Many aerospace components are made from lightweight alloys that require precise finishing.

Vapour blasting provides a controlled method for cleaning and preparing these materials without compromising their structural properties.

Engineering firms also use the process to prepare parts for inspection or assembly.

Manufacturing and Maintenance

In manufacturing environments, vapour blasting is used to clean moulds, dies, and production equipment, helping maintain accuracy and prolong service life.

It is also used to refurbish parts before recoating or reassembly, improving efficiency in maintenance workflows.

Choosing the Right Conditions for Vapour Blasting

Source: ts-engineering.co.uk

Successful vapour blasting depends on several variables, including the type of abrasive media, the slurry concentration, water flow, and pressure settings.

Fine glass bead is commonly used for producing smooth, bright finishes, while aluminium oxide or other harder abrasives may be required for more stubborn contamination.

Humidity, temperature, and the condition of the component also play roles in determining the final result.

Proper cleaning and drying after blasting are essential to prevent flash rusting or surface residue.

The Role of Vapour Blasting in Modern Industry

As industries place greater emphasis on precision, safety, and environmental considerations, vapour blasting continues to gain relevance.

Its ability to deliver high-quality finishes while controlling dust, reducing wear, and preserving material integrity makes it a reliable choice across numerous disciplines.

Whether used for restoration, manufacturing, or specialist engineering tasks, the process provides a balanced approach to surface treatment that aligns with modern standards for cleanliness and accuracy.