You are here, and we are here. The issue we have is one of a kind. The same one. Ball screw nut. This is not something you’ll encounter every day. But a day will come when you will. The best course of action is to prepare yourself. That’s why we’re here. That’s why you’re here. We can do this together. Understanding ball screws is not an easy task. We are talking about actuators. Not any kind. Linear ones.

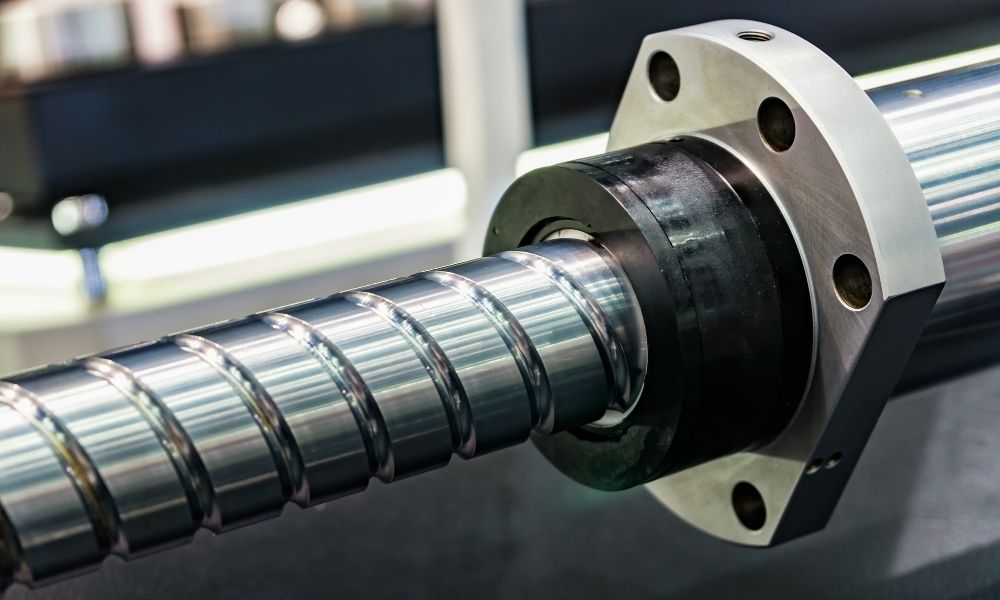

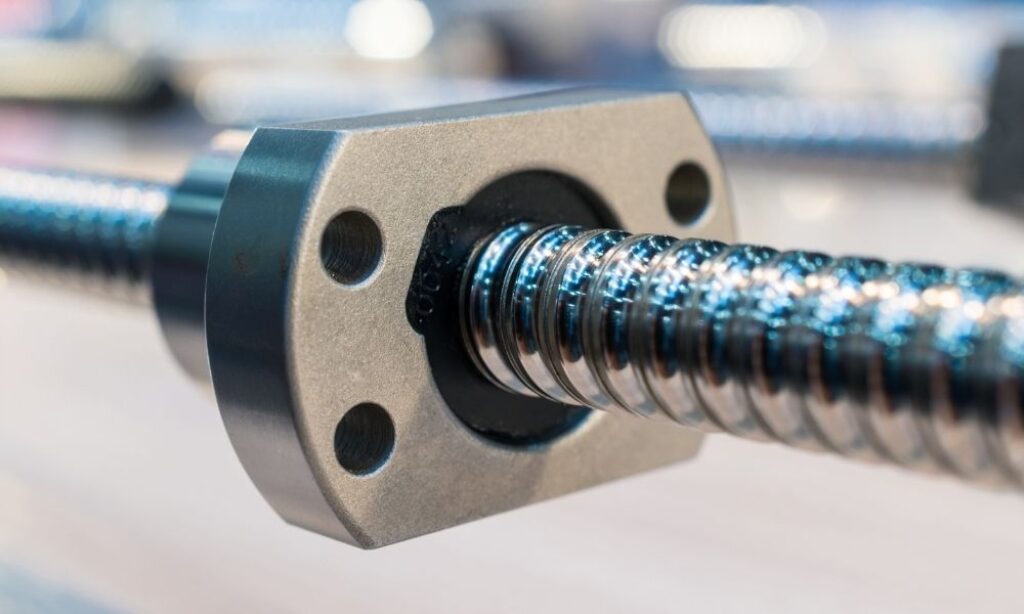

In most cases, they consist of two main parts. The first one is the screw shaft. The second one is a nut. The latter is a little bit more important as it contains one quite important ball. Why is this ball important? Well, it’s simple. You’ll notice that these screws have identical helical grooves. This ball is what rolls between them, making this mechanism work. Do you understand them now a little bit more? Let’s put it simply. This screw is what makes rotational motion become linear motion. How about the nut? It is no less important as it translates the load, either dynamic or stationary, with exceptional accuracy, repeatability, and of course precision.

Table of Contents

How to Install One?

Source: nskamericas.com

Now, this might sound like a difficult task, but you can handle it. It is done in a few simple steps. Once you get a hang of one ball screw, you’ll be able to handle hundreds with ease. The first step is to position the ball nut the right way in order for the flange to be able to be mounted on it. Once this is done you need to focus on its front end. There you’ll find the part which is called the ‘wiper’ that needs to be mounted to the screw too. Step three is the most important one. It is the one we already partially described. It is where the ball screw finds its way to the ball nut or vice versa whichever way you like more. Once this is done, the time is right to get over with the wiper kit. As you’ll notice we’re not skipping anything which is a signal that every step is vital for a successful installation. Once you have everything from above in order the time is for the lubrication process to begin. You mustn’t skip it under any circumstances. When this part is done you can complete the process by making use of the screw and putting it in your machine or wherever you intend to use it.

If you think that this was the hardest part of the process, you’re wrong. Maintenance is harder. Many people tend to believe that it is not necessary and that it’s not something you’ll do frequently but that’s not the case. That’s why we’re going to dedicate a few paragraphs to the tips tied to maintenance. So, please do not stop the reading process here, but continue reading right up till the end.

Installing

The first step of maintenance with this mechanism starts with the installation process. You need to ensure that everything is set the right way and that there are no foreign elements in both the screw and the nut or nowhere in between. If there’s some debris left in any of the components your screw might not work properly from the start and it will need maintenance straight away. That’s why it is vital that you do the installation process the right way and avoid this issue straight away.

Keep It Clean

Source: wedin.com

You might get the impression that we are repeating ourselves. That’s not the case. We can’t stress enough how important it is to keep this mechanism and all of its components clean. Everything needs to be kept tidy. You start with bearing journals and you end with a ball screw. We’re not even going to mention mounting surfaces. Keep everything clean. It is important beyond the measure of common sense. This needs to be done with surgical precision and the same amount of cleanliness.

Align Everything

Install, clean, and align. So far so good. Simple, isn’t it? If you want a screw ball to work properly and as it should, you need to align it the right way. Being correct in this domain is quite important too. To bless it with longevity and to function as it’s intended you need to get the job right with the alignments. You need to install everything parallelly so that every component, starting with the ball nut is tightened as it should be.

Lubrication

Source: wedin.com

Here we are. Do not think that maintenance is non-existent with ball screw nuts. It is. You need to be dedicated to it. If you handle everything from above why you should, the job is only half done. Yes, this mechanism requires little to no maintenance when you do everything by the book. But, this is why you need to keep reading this article. Lubrication. It is where it all starts, or it ends if you don’t do it. When you lubricate it as often as is recommended you’re ensuring its longevity. In the end, it is all you ever wanted or needed when you first started assembling a ball screw nut. So, whatever you do, never forget to have lubricant nearby, and to access the mechanism on need, even before you notice that it’s not working as it should. Lubrication is the key to success.

Transportation

Here’s one important part of this mechanism. If you assemble it before transportation, you need to do a check-up before installation. This is vital beyond any measure. During transport, many things can go wrong, especially if the driver is not aware of what he’s transporting. This is where you need to be diligent. First of all, you need to ensure that the components are not exposed to moisture. Once this is ensured you need to keep it protected from any outside influence. Even the smallest particles of debris can cause harm. Last but not least you need to keep it tied up. If it’s allowed to flow in the cargo space the chances are it will be damaged. Avoid this if transportation is needed.